Applications

-

Decorative PVD

In order to obtain high quality decorative color, we usually use AIP(arc ion plating) in PVD technology. It produces durable colors. The main coatings is TiN(titanium nitride) and it’s golden. The work temperature for AIP coating is more than 150 centigrade, so it is suitable for glass, ce...Read more -

Plastics

Vacuum metallizing is used for different plastics. The most common technology we use is aluminum evaporation. We can get chrome like color on plastics very fast in a metallizing machine. The raw material is usually aluminum. The added value for plastic items are not high, so we usually make metal...Read more -

Car Accessories

Vacuum metallizing in PVD coating is used for car accessories. The technology we use is aluminum evaporation or magnetron sputtering. We can get chrome like color on plastics very fast in a metallizing machine. The raw material is usually aluminum or chrome. But protective painting is necessary ...Read more -

Glass

There are two reasons to apply PVD coatings on glass: To make it with decorative appearance or to make it with functional coatings. PVD technology can be used for high class glass lighting accessories(e.g, crystal lights). PVD coatings can improve the transparency or reflection rate of the gla...Read more -

Ceramic

We apply decorative colors on ceramic items with AIP(arc ion plating) in PVD technology. It produces durable colors, such as golden, silver, etc. The main coatings is TiN(titanium nitride) and it’s golden. The raw material is titanium. And for silver color, the raw material can be stainles...Read more -

Mirror Glass

There are two ways to apply reflective mirror finishing on glass. Vacuum metallizing coating also can be used for small batch type vacuum coatings machine for aluminum mirror production. For large output projects, we recommend continuous inline magnetron sputtering systems for silver mirror manu...Read more -

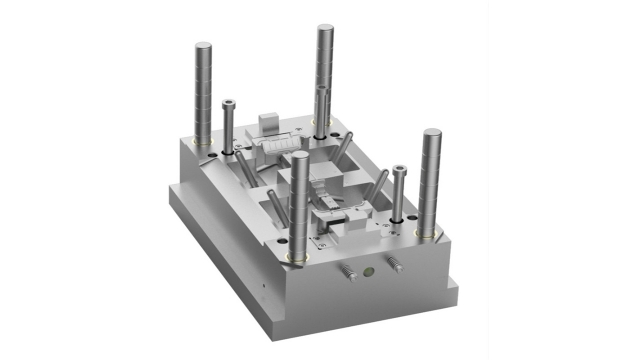

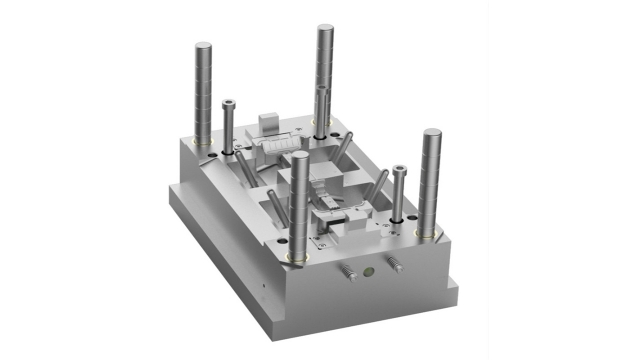

Molds

PVD Vacuum Coating System is designed for hard and super hard protective coatings on tools, cutter and molds. After PVD coating, the lifetime and work performance of tools can be improved a lot. PVD system can deposit TiN, CrN, AITiN, TiCN,TiAISiN, multilayer super hard coatings, which is used i...Read more -

Golf Head

Magnetron sputtering in PVD coating is used for golf head. The most common colors are bright chrome, dark chrome, golden color, black color. Medium frequency magnetron sputtering is involved to develop more possibilities of colors. There are 2 cathodes in a set of MF magnetron sputtering system....Read more -

ITO Conductive Glass

ITO conductive glass coating equipment adopts vacuum magnetron sputtering technology and unbalanced magnetron sputtering technology to coat high quality float glass with SO2/ITO layer. Based on international advanced control system. The whole manufacturing process works automatically and continuo...Read more -

Sanitary

PVD arc ion deposition machine adopts arc ion deposition system and magnetron sputtering technology to realize multi-function coating effect. They are widely used in coating one or more layers of metal coating on surface of metal spare part and metal materials such as TIN coating, gold-like coati...Read more -

Gun Accessories

PVD coaters are used for gun accessories. The common color is golden, black. The easy way to obtain golden color is use arc ion plating to make titanium nitride coatings. Black is a kind of oxidation color in PVD color. All the accessories put into the PVD chamber must be after pretreatment. PVD...Read more -

Jewellery

Decorative PVD is involved in applying colors on small pieces, such as jewellery or watches. Golden, rose golden, black are the most common colors. The coating technology can be arc ion plating or magnetron sputtering. The power produced by arc ion plating is strong. The particles made by AIP is ...Read more