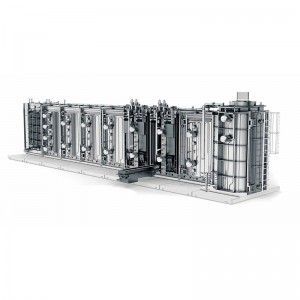

Vacuum chroming machine for Mannequins parts

Application

Vacuum chroming machine is designed for fast vacuum plating on plastic materials. After vacuum coating process, we can apply gold, silver, red, purple, blue, gray, black and other colors

The machine can come with 1 or 2 doors.

The advantage of a 2 doors vacuum chrome machine is, you can load products into one of the doors, and close the other door, and start the coating process.

Painting line and oven is necessary for the metallizing process.

Features

Good structure to improve productivity

The coating layer is high glory

The price of raw material is low

The operation is easy and automatic

Maintenance is convenient

Low energy consumption and stable performance

Application industry

Widely used in automobiles, plastic decorations, mannequins parts, sanitary wares, handles, plastic caps, clocks and toys, mobile phones, cosmetics, toys and other industries.

What are your company’s advantages?

1. A complete set of our own team to support your selling.

We have outstanding R&D team, strict QC team, exquisite technology team and good service sales team to offer our customer the best service and products. We are both manufacturer and trading company.

2. We have our own factories and have formed a professional production system from material supplying and manufacture to sale, as well as a professional R&D and QC team. We always keep ourselves updated with market trends. We are ready to introduce new technology and service to meet the market needs.

3. Quality assurance.

We have been producing and designing non-standard vacuum coating machines for 14 years. We have rich production experience and are very familiar with the market. We are also very familiar with the quality stability of product accessories.