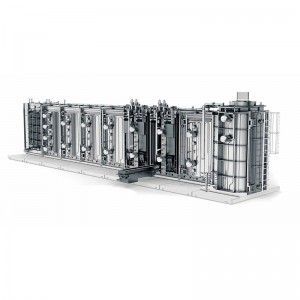

Vacuum coating machine for ABS plastic parts

Setup of the Vacuum Metallizing Machine

-One/Two Doors

Frame and chamber are made of carbon stainless steel.

Each door provides an inspection window for the visual control of the process. The door walls provide a stainless steel liner which is easily removal for maintenance.

-Customized Vacuum Chamber

The chamber provides inner stainless steel liners easily removal for cleaning.

The pumps stand on its rear part.

The chamber has a series of small flange for the purpose of measuring.

-High vacuum pumping system

Diffusion pump+Booster pump+Mechanical pump

-Vacuum measuring and control

With metal Pirani gauge+metal Ionization gauge

-Fixtures moving system

-PLC Control unit

-Aluminum evaporation system with high power transformer

-Iron frame

Features

The structure is reasonable

The film layer is uniform

Film forming quality

High pumping speed, short working cycle and high production efficiency

Operation is convenient

Low energy consumption and stable performance

Application industry

|

Model Number |

EV-1000 |

EV-1200 |

EV-1400 |

EV-1800 |

EV-2000 |

Two doors or Two chambers model are available |

|

|

Dimension of vacuum chamber(diameter*height) |

1000*1100 |

1200*1400 |

1400*1600 |

1800*2000 |

2000*2200 |

||

|

Material of vacuum chamber |

Carbon steel, SUS304 or SUS316L |

||||||

|

Technology of working |

vacuum resistance evaporation with tungsten& aluminum filaments, high power evaporation transformer |

||||||

|

Pumping system |

Diffusion pump+mechanical pumps, booster pump |

||||||

|

Pumping Time |

From atmosphere to 5.0*10-2Pa less than 8 minutes |

||||||

|

Vacuum Limit |

5.0*10-4 Pa |

||||||

|

Working temperature |

Room temperature |

||||||

|

Working mode |

Automatic or Manual mode, by 10.4 inches PLC touches screen |

||||||

|

Total Power |

40-80kW |

70-140kW |

|||||

|

Footprint |

2*2 meters |

2*3 meters |

3*3 meters |

3*3 meters |

3*4 meters |

4*5 meters |

5*6 meters |

|

These units you can custom made |

1. Size of vacuum chamber 2. Configurations of pumps |

||||||

|

Optional instruments |

1. Leakage detector 3. Arc ion deposition system 4. Magntron sputtering system |

||||||