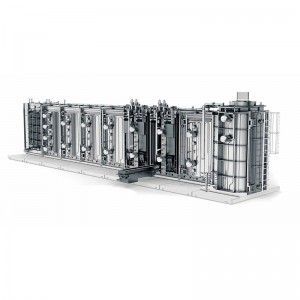

Aluminum Mirror Inline Magnetron Sputtering Line

Main features

- Aluminum Mirror Inline Magnetron Sputtering Line is usually comes with multiple vacuum chambers to complete of the vacuum coating on glass sheets.

- Main features:

- 1.Max.glass coating size:2440x3660mm or customized

- 2. Multi-vacuum chambers and multi-sputtering chamber design are available

- 3. The horizontal magnetic control line has single-end and double-end structure; glass double cleaning, coating, detection, painting, drying, cooling can be finished all at one time

- 4. The sputtering coating line uses PLC for whole process control and is equipped with color screen to show the coating process data

Layer of coatings: Titanium, Chrome, Stainless Steel, Aluminum, Silver, Copper, etc.

- Compound: TiN, TiO2, etc.

- Layer thickness: 5-100nm

- Transmission: 8-40% at 380-780 nm wavelengths

- Deposition temperature: room temperature

- Ultimate pressure after 8 hr pump-down:

- Entry lock chamber & vacuum lock chamber: 5×10-1 Pa or below

- Buffer Chamber 1 : 3×10-3 Pa or below

- Sputtering Chamber: 2×10-3 Pa or below

- Buffer Chamber 2 : 3×10-3 Pa or below

- Exit lock chamber & vacuum lock chamber: 5×10-1 Pa or below

Write your message here and send it to us