Products

-

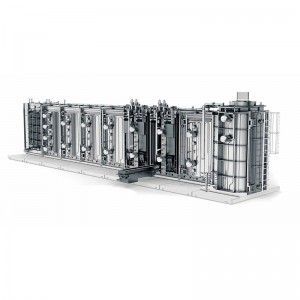

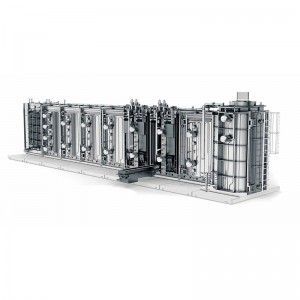

ITO Glass Magnetron Sputtering Coating Line

ITO Glass Magnetron Sputtering Coating Line adopts vacuum magnetron sputtering technology and unbalanced magnetron sputtering technology to coat high quality float glass with SO2/ITO layer. Based on international advanced control system. The whole manufacturing process works automatically and continuously.

-

Vacuum deposition magnetron sputtering system

Vacuum deposition magnetron sputtering system is a kind of vacuum equipment which can be used for applying thin film coating layers on different raw material with metallic or functional coatings.

-

Magnetron sputtering coating machine for plastic disposable cutleries

Magnetron sputtering is a widely used thin film deposition technology at present. With the continuous development of sputtering technology and the exploration of new functional films, the application of magnetron sputtering has been extended to many fields of production and scientific research. As a non-thermal coating technology in the field of microelectronics, it is mainly used in chemical vapor deposition (CVD) or metal organic chemical vapor deposition (MOCVD) to deposit thin films of materials that are difficult to grow and unsuitable, and can obtain very uniform thin films in large areas.

-

Aluminum Mirror Inline Magnetron Sputtering Line

Aluminum Mirror Inline Magnetron Sputtering Line is designed for high output of glass mirror manufacturing purpose. In order to coat bigger glass and take care about fragile glass panel, especially for the large size sheets, we usually make horizontal type of sputtering line. It is a continuous magnetron coating line, with the front and rear rough pumping chamber, and after the transition chamber, before and after the fine pumping chamber, a buffer chamber, color plating room.

Target d esign: cylindrical magnetron sputtering cathodes or/and planar cathodes.

Power source: power supply with high power DC or MF magnetron sputtering

Drive system: roller drive, frequency adjustable, induction type room door opening system.

Vacuum system: diffusion pump (or turbo molecular pump) + roots pump + mechanical pump

-

vacuum metallization coating machine

Vacuum metallization coating machine, is to heat the coated aluminum wire material in a vacuum chamber to a certain temperature so that it evaporates and enters the space in the form of molecules or atoms to achieve the purpose of coating. The vacuum coating is uniform, the adhesive force is strong, the mechanical property and the chemical property of the tool are improved, and meanwhile, the purity of the film is very high, the compactness is good, and the surface is bright, thereby greatly improving the yield of products.

-

Vacuum coating machine for headlamps

Vacuum coating machine for headlamps, is to heat the coated aluminum wire material in a vacuum chamber to a certain temperature so that it evaporates and enters the space in the form of molecules or atoms to achieve the purpose of coating. The vacuum coating is uniform, the adhesive force is strong, the mechanical property and the chemical property of the tool are improved, and meanwhile, the purity of the film is very high, the compactness is good, and the surface is bright, thereby greatly improving the yield of products.

-

Vacuum coating machine for ABS plastic parts

Vacuum coating machine for ABS plastic parts, is to heat the coated aluminum wire material in a vacuum state to a certain temperature so that it evaporates and enters the space in the form of molecules or atoms to achieve the purpose of coating. The vacuum coating is uniform, the adhesive force is strong, the mechanical property and the chemical property of the tool are improved, and meanwhile, the purity of the film is very high, the compactness is good, and the surface is bright, thereby greatly improving the yield of products.

-

small PVD coating machine for jewellery

small PVD coating machine for jewelery is a smart design to make coatings on small sizes substrates. It uses PVD vacuum technology to obtain different colors in vacuum plasma chambers. Arc ion plating is the easiest PVD technology to obtain golden efficiently.

Arc ion plating produces a lot of heat during the process, so it is usually used for metal(mainly stainless steel), glass and ceramic items. -

Hybrid PVD machine for hard coatings

Hybrid PVD machine for hard coatings comes with magnetron sputtering and arc deposition technologies to obtain PVD hard coatings on substrates.

Main application: hardwares, tungsten carbides, cutting tools, mold and dies, punches, drills, etc. -

small PVD coating machine for watches

As an experienced manufacturer of PVD coating system, Hongfeng VAC provides customized solutions for their clients. From the vacuum coater with big vacuum chamber and small size chamber or even the mini smart PVD system for laboratory and research applications.

The vacuum pumping system can be with economic diffusion pump and high quality turbo molecular pumps.

We even provide all accessories of the PVD machine for our clients. Such as arc cathodes, magnetron sputtering cathodes, mass flow controllers, vacuum pressure sensor, pirani gauge and ion gauges, target materials, vacuum pumps and vacuum pump stations, etc.We produce small PVD coating machines for decorative applications on small items, such as jewellery, watch shells, etc. The colors can be rose golden, gold, black, blue, etc.

-

Functional Cathodic Arc Deposition machine

Functional Cathodic Arc Deposition machine uses arc deposition vacuum technology to obtain PVD hard coatings on substrates. Titanium nitride coating is the most universal coatings for the involved items.

The hard coating PVD coating machine can apply titanium nitride, titanium carbide nitruro, titanium aluminuro nitruro, chrome nitruro, DLC and other hard coatings for tools, molds, hardware and knives. Our company has extensive experience in these applications.Main application: hardwares, tungsten carbides, cutting tools, mold and dies, punches, drills, etc.